Revolutionize Your Frozen Leafy Vegetable Production with Our Tailored Solutions

Are you seeking to elevate your frozen leafy vegetable business with a production line that's optimized for delicate greens? Our cutting-edge equipment is designed to preserve the vibrant color, crisp texture, and nutritional integrity of leafy vegetables while maximizing efficiency and yield.

With a deep understanding of the unique challenges and opportunities in leafy vegetable processing, we offer a comprehensive range of solutions tailored to your specific needs. From gentle blanching to precise freezing and efficient packaging, our line ensures a seamless workflow that delivers superior quality products.

Discover how our innovative technology can help you:

- Maintain Leaf Integrity: Our specialized equipment minimizes damage to delicate leaves, preserving their appearance and texture.

- Optimize Color Retention: Our precise temperature control and rapid processing techniques help lock in the vibrant color of leafy greens.

- Enhance Nutritional Value: Our gentle handling and efficient freezing methods preserve essential nutrients and antioxidants.

- Increase Production Efficiency: Our high-speed machines streamline your operations, allowing you to process larger volumes while maintaining quality.

- Reduce Waste: Our advanced equipment minimizes product loss and maximizes yield.

Ready to transform your frozen leafy vegetable production? Contact us today to learn more about our tailored solutions and how we can help you achieve your business goals.

Frozen Leafy Vegetables Production Line Steps:

• Material Feeding Stage

Material Feeding Stage: The Foundation of Frozen Leafy Vegetable Production:

The material feeding stage is the critical first step in the frozen leafy vegetable production process. It involves the efficient and consistent delivery of fresh, high-quality leafy vegetables to the processing line. This stage significantly impacts the overall quality and efficiency of the final product.

Key considerations in the material feeding stage:

• Freshness and Quality: Ensuring that the leafy vegetables are delivered to the processing line in a fresh and undamaged state is paramount. This requires proper harvesting, storage, and transportation practices.

• Uniformity: Consistent feeding of leafy vegetables with uniform size, shape, and moisture content is essential for efficient processing and consistent product quality.

• Cleaning and Sorting: Removing any foreign material, such as dirt, insects, or damaged leaves, is crucial to prevent contamination and ensure the safety of the final product.

• Feeding Equipment: The choice of feeding equipment depends on the specific type of leafy vegetables being processed and the desired throughput. Options include conveyor belts, hoppers, or automated feeding systems.

• Feeding Rate: Controlling the feeding rate is important to maintain a steady flow of vegetables to the subsequent processing stages, preventing bottlenecks and ensuring optimal machine performance.

• Preparation Stage

Preparation Stage: Key Component for Leafy Vegetable Processing:

The preparation stage in frozen leafy vegetable production is essential for ensuring the quality and safety of the final product.

Here are the key components and their functions:

1. Sand Remover:

• Removes sand and other gritty particles from the leafy vegetables.

• Typically uses a combination of water jets and agitation to separate impurities.

2. Washing Machines:

• Thoroughly clean the leafy vegetables to remove dirt, debris, and pesticide residue.

• May involve multiple stages with different water temperatures and agitation levels.

3. Manual Inspection Station:

• Identifies and removes damaged, discolored, or defective leaves.

• Ensures product quality and prevents the inclusion of substandard material.

These components work together to prepare the leafy vegetables for further processing, such as blanching and freezing. A well-equipped and efficient preparation stage is crucial for producing high-quality frozen leafy vegetables.

• Blanching Stage

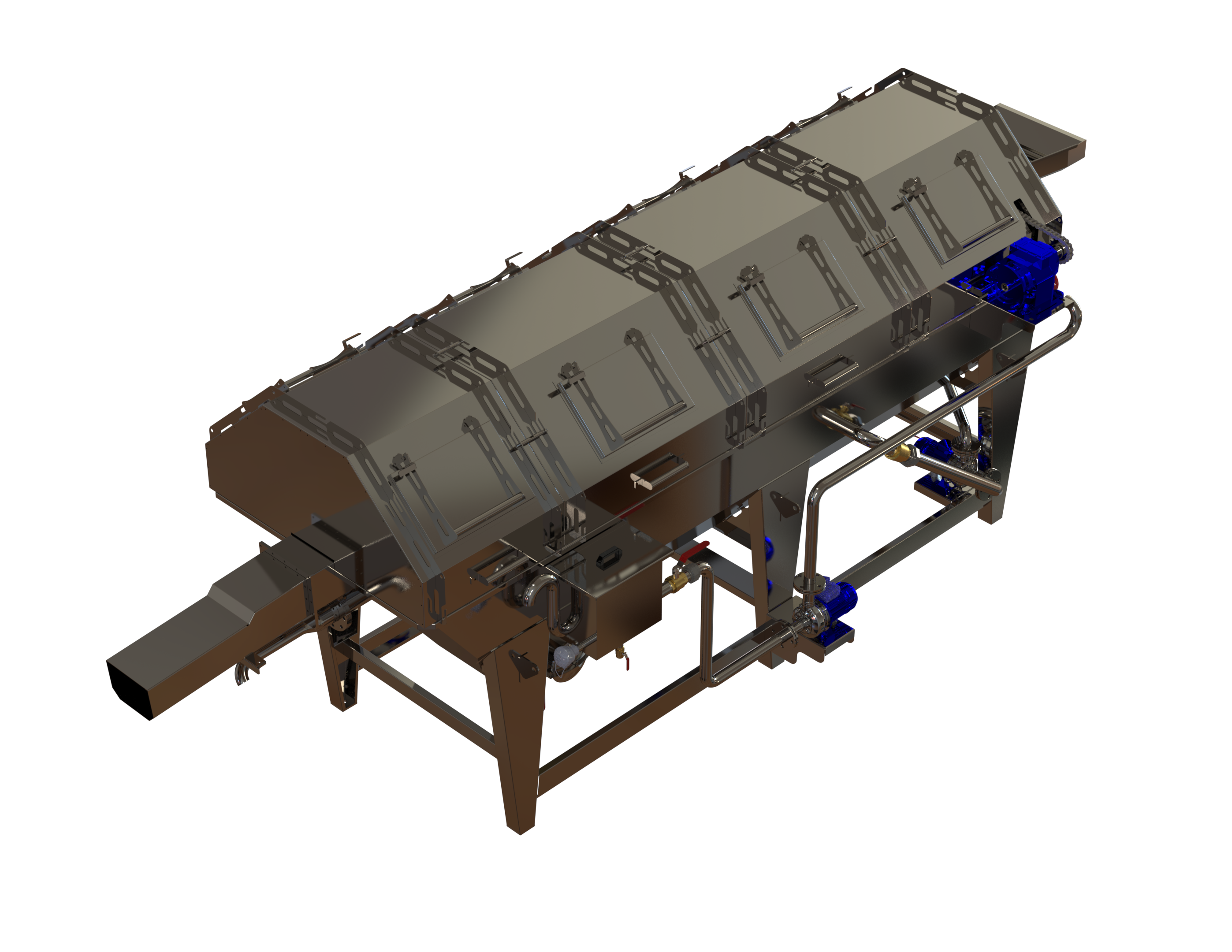

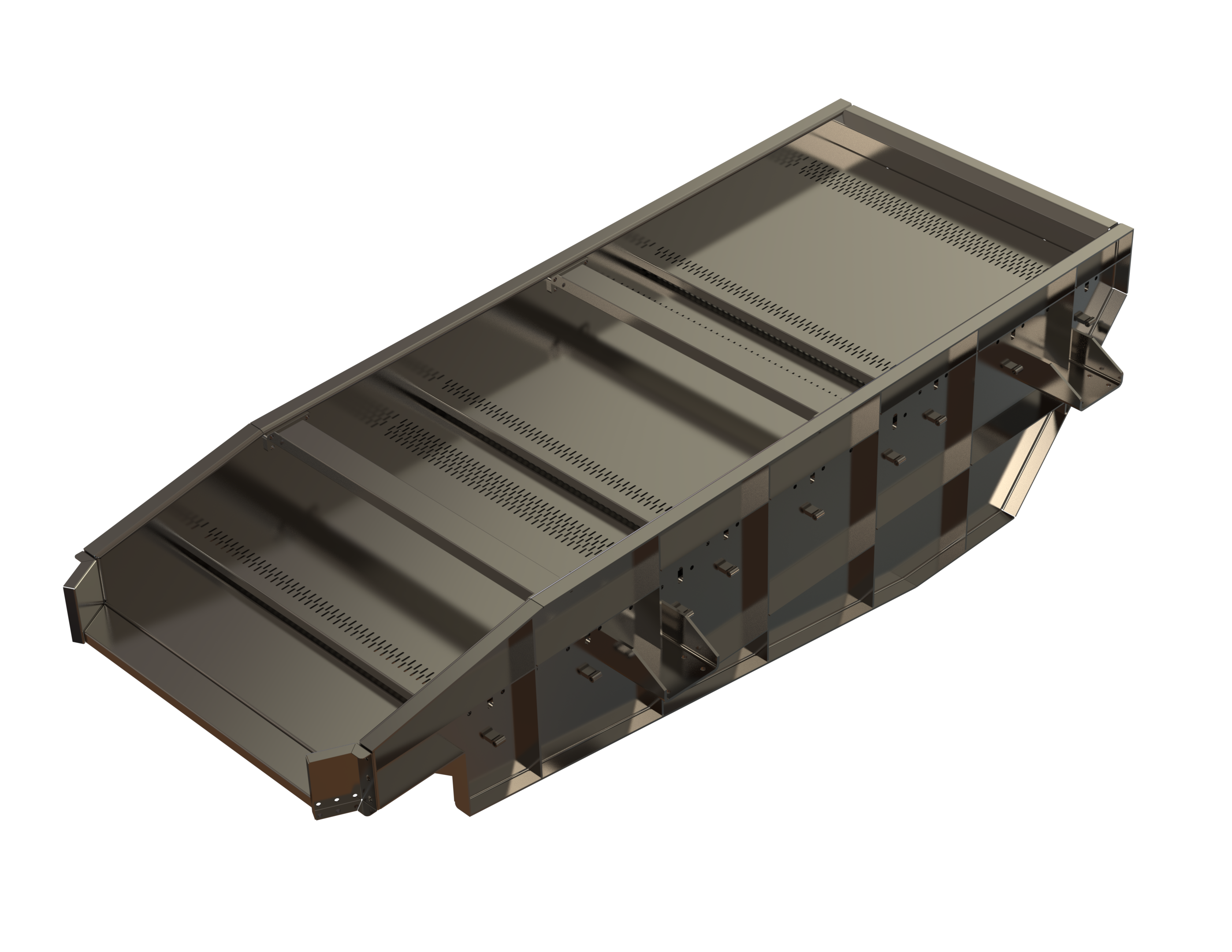

Blanching Stage: Preserving the Goodness of Leafy Vegetables:

The blanching stage is a critical step in frozen leafy vegetable production, designed to inactivate enzymes, set the color, and prepare the vegetables for freezing. It helps to maintain the texture, flavor, and nutritional value of the product.

Key components and processes in the blanching stage:

• Dewatering and Rinsing: Leafy vegetables are rinsed with fresh water to remove any residual dirt or impurities before blanching.

• Heating: By Spraying Hot Water: The vegetables are exposed to a high-temperature spray of hot water to quickly heat them. With Direct Steam Injection: Steam is directly injected into the blanching chamber to rapidly raise the temperature of the vegetables.

• Cooling: With Cold Water: Immediately after blanching, the vegetables are cooled in cold water to stop the cooking process and prevent overcooking.

Blanching Process Specifications:

• Type: Direct steam heating with water cooling.

• Capacity: Based on the volume of leafy vegetables being processed.

• Products: Molokhia and Spinach.

• Blanching Time: Adjustable from 5 to 25 minutes.

• Zones: Separated by air knife curtains for isolation.

• CIP: Cleaning-in-place system included for efficient cleaning.

• Conveyors: Plastic modular, heavy-duty, food-grade conveyors.

• Product Cooled: Up to 10±20°C using cold water and a falling heat exchanger.

• Heating Temperature: Adjustable up to 96°C.

• Steam Leakage: No steam leakage from the heating zone to other zones.

Mincing Process:

• Equipment: Specialized equipment for cutting and grinding leafy vegetables into small pieces.

• Capacity: 3000 kg/hour, including yield percentage.

• Cutting Sizes: 2 mm, 5 mm, 7.5 mm, 20 mm.

• Process: Fully automatic, from receiving blanched leaves to cutting, grinding, and feeding to a buffer tank. Minced Leaf Filling Machine:

• Type: Fully automatic form-fill-seal machine.

• Capacity: 3000 kg/hour.

By effectively managing the blanching and mincing stages, frozen leafy vegetable producers can ensure the quality, safety, and shelf life of their products.

• Spiral IQF

Spiral Freezer Stage: Preserving Leafy Vegetables at Peak Quality:

The spiral freezer (IQF – Individually Quick Frozen) is essential for freezing blanched leafy vegetables while maintaining their natural color, texture, and quality.

Key Benefits:

Natural Look: Maintains color and appearance.

Hygiene & Safety: Stainless steel build with sequential defrosting prevents contamination.

Efficiency: High throughput and reliability.

Energy Saving: Low power use with consistent freezing performance.

Product Safety: No belt lubrication needed, reducing contamination risks.

Minimal Downtime: Designed for continuous operation.

Fast Defrosting: Optional steam-defrost system speeds up turnaround.

Technical Specs:

Type: Spiral freezer with horizontal airflow

Capacity: 3 tons/hour

Refrigerant: Ammonia (NH3)

Defrosting: Hot gas & sequential system

Evaporation Temp: -40°C

Output Temp: -18°C Retention

Time: 10–20 minutes

Construction: Stainless steel frame and pipes.

This system ensures frozen leafy vegetables stay fresh, safe, and visually appealing for consumers.

• Packaging Stage

Protecting and Presenting The Frozen Leafy Vegetables:

The final step in frozen leafy vegetable production as packaging ensures product protection, quality preservation, and consumer information.

Packaging Options:

Minced Molokhia: <3 mm, 400g in transparent PE inside printed PE.

Minced Spinach: <3 mm (minced) or <20 mm (pureed), 400g in PE packages.

Packaging Method:

Flow Wrapping: Seals product in continuous film—ideal for retail.

Key Considerations:

Material: Must resist freezer burn and contamination.

Size/Shape: Fit product and market needs.

Labeling: Clear info—name, weight, ingredients, nutrition.

Branding: Should reflect identity and attract buyers.

Proper packaging boosts shelf appeal and ensures product safety from production to purchase.